Electric forklifts are much more efficient than their conventional counterparts, providing prolonged savings in both energy and maintenance costs. However if electrical batteries are not cared for properly, any efficiencies will not only quickly diminish, but affect the overall performance and operational life of a forklift.

Here at Forkserve with over 40+ years of experience in the field, we’ve been pioneers in the field of battery regeneration. We saw life where others did not, and revolutionised the industry.

In order to get the most out of your forklift battery, we’ve composed this handy guide of best practice steps to follow. Following proper battery maintenance will decrease your expenses, improve battery safety and maintain your forklift’s overall performance.

Charging the battery at the correct state of charge

We recommend not excessively charging your battery. The optimum time to commence recharging a battery is at 25% state of charge (SOC).

Avoid the temptation to opportunity charge (i.e. charge during daytime breaks), this practice leads to excessive heat and the need for charging to occur more frequently, thereby ultimately decreasing the batteries efficiency and overall useful life.

It’s best to charge your battery overnight, allowing a suitable cool down period after charging.

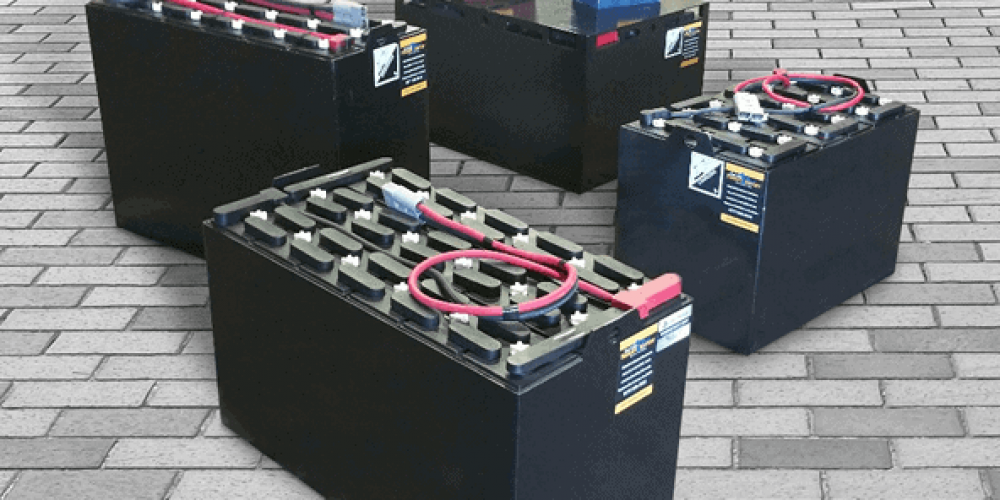

Checking the condition of the battery for corrosion

Good maintenance practice requires the regular checking of battery leads and plugs. If you notice any build-up of corrosion (i.e. corrosion on the battery case), this is a common sign that your battery is worn out and has outlived its usefulness.

Worn out batteries may not put out a sufficient charge to safely power a forklift, and in fact can produce unstable electrical output causing damage to forklift systems. If you suspect your battery may be corroded, do not attempt to repair it yourself, but instead call an authorised repairer.

Maintaining water levels in the battery

Water plays a very important role in maintaining the health of a battery as it, mixed with the sulphuric acid, allows the flow of electricity between the internal lead plates when charging or discharging.

It’s necessary to maintain the right level of water to ensure optimal performance. If the water level drops too low, the active material dries out and becomes brittle, which permanently damages the battery and shortens its useful life. If the water level is too high, this will overflow, spilling sulfuric acid that burns skin and erodes floors.

It is also important to only use distilled water when topping up a battery to avoid introducing contaminates from tap water that can cause damage to your battery. We recommend checking the water level regularly and adding water if you notice that the water level has come down. This generally should be done once weekly and always after charging.

Using the correct charger for the battery

There are different sized chargers for different batteries. If the charger is too big or too small, it won’t be able to charge your forklift battery adequately. Hooking your forklift battery up to an incorrect charger can also result in malfunctions, non-charging or a fried battery.

We recommend that you first assess your current charging station and determine that you have the correct setup for your equipment’s battery size. If it’s not a proper fit, you will need to upgrade your charger. You should also make sure each charger has clear labels, and adequately train staff to determine which battery goes to what charger.

Allow the battery to fully charge before removing the unit from the charger

We recommend letting a forklift battery charge completely once you’ve started to charge it.

Cutting a charging cycle short can be harmful to the battery’s longevity.

The lifespan of the battery is generally determined by how many charge cycles it has undergone.

If a battery is charged for only a short while, it will need to be recharged again more frequently. Over time, this practice decreases the battery’s efficiency and ultimately affects its useful life.

Electrical batteries are the lifeblood of forklifts and play a critical role in delivering optimal performance. The average electric forklift battery’s useful life is approximately 5 years. However, if sufficient care and maintenance is taken you can extend its lifespan for up to 10 years.

Here at Forkserve, with over 40 years of experience in the field, we’re experts in the field of optimal battery maintenance. We recommend always ensuring you use the correct charger for the battery, allowing the battery to fully charge before removing the unit from the charger, and maintaining an adequate water level post charge.

Avoid the temptation to opportunity charge and only charge a battery when it is at 25% SOC.

Remember to check for any signs of corrosion, and do not attempt to repair your forklift battery, instead call an authorised repairer.

Following proper battery maintenance will decrease your expenses, improve battery safety and maintain a forklift’s overall performance. If you have any further questions on battery maintenance and longevity, why not contact the experts here at Forkserve.