In any operational environment, safety should be the number one concern, this is particularly so when operating a forklift in a busy workplace environment. Operating a forklift without undertaking, the appropriate training or having a good working knowledge about this important piece of machinery can lead to accidents and further unfavourable consequences.

One safety mechanism that plays a vital role in forklift operation is the forklift load plate. This plate contains critical information that informs forklift operators what the safe working load limits apply to the specific forklift. Forklift Operators need to be aware of, and know how to interpret the load plate in order to safely operate the forklift within its operational limitations.

Here at Forkserve we’re passionate about safety and making sure our customers have all their right tools to operate their forklifts safely. We’ve put together this guide to better explain forklift load plates and how they can be used to operate a forklift safely and efficiently.

What Is A Forklift Load Plate?

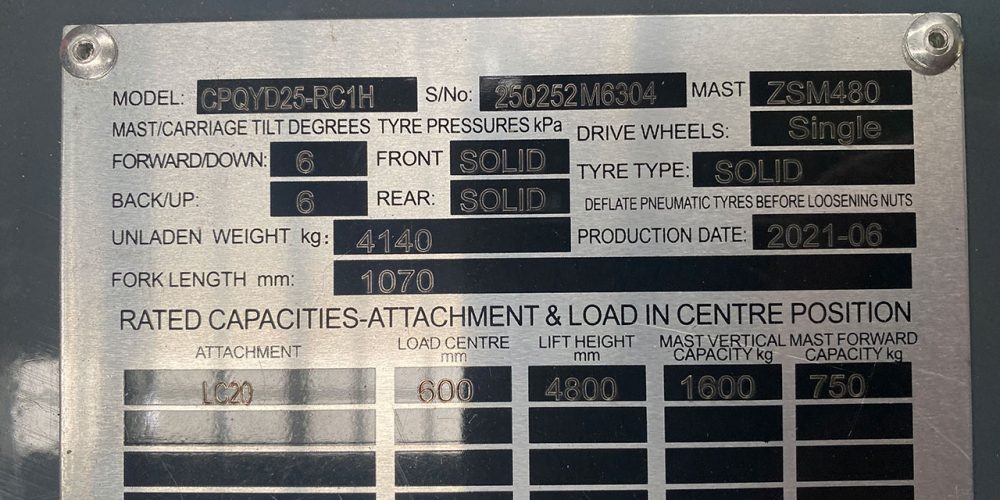

A forklift load plate is a placard installed on a forklift that provides essential information about the configuration, design, and limitation of a forklift. It contains important data specific to the particular machine such as the weight, fuel type, and overall load capacity depending on the terrain, load height and tilt of the forklift mast.

This plate is a requirement of OSHA regulation 29 CFR 1910.178(a)(3) and must be displayed on the instrument panel near the operating controls on all forklifts approved for service.

Different parties handle the installation and ongoing maintenance for this plate. The manufacturer based on data provided by a nationally recognised testing laboratory initially installs it. It is then up to the operator to adequately maintain the plate to ensure it is up to date and complete.

What Type Of Information Is On A Forklift Load Plate?

A forklift data plate is a crucial safety aid. It’s designed so that operators can easily and quickly learn information about the particular forklift they will be operating. While the specific data contained in the plate can vary across manufacturers, they typically contain the following:

| Type | Details |

|---|---|

| Model Number | Provides a good overall summary about a forklift’s specifications including series, tyre type, fuel type, and lifting capacity.

This number is important in communicating with dealers and repair personnel for technical assistance. |

| Serial Number | Forms a key component for any communication with technicians. It will enable a technician to narrow down technical information and match parts for any needed repairs. |

| Mast Type | Indicates the type of mast depending on the model (2-stage, 3-stage, or 4-stage). |

| Fuel Type | This indicates how a forklift is powered and can include electricity (E), liquid propane (LP), diesel (DS), gasoline (G), or compressed natural gas (CNG). |

| Tilting Angle | Lists the maximum angle in which a mast can tilt forward and backward.

Is useful as depending on what materials are being carried, may require a higher tilt angle to ensure stable manoeuvrability and avoid any loss of loads. |

| Attachments | Lists what attachments if any have been added to the forklift. This data is necessary as any attachments will reduce lifting capacity affecting a forklift’s overall capabilities. |

| Front Tread | Lists the measurement of the overall width of a forklift. It is the equivalent of a forklift’s footprint and enables an operator to factor in the space required for operation in a workplace environment. |

| Tyre Size | Indicates both the type and size of the tyre a forklift uses. It’s important to match the type of tyre to what the forklift has been designed to use. Common labels include Solid – Solid pneumatic tyres, Smooth or Treated – Cushion type tyres. |

| Truck Weight | Lists the overall weight of the truck, that is, how much the forklift weighs without a load. |

| Forklift Diagram | Lists important data used to calculate the load weights and overall forklift manoeuvrability. This includes

1) Horizontal load centre 2) Vertical load centre 3) Maximum fork height 4) Maximum offset distance for forks from the centreline |

The tilting angle is the maximum angle in which a mast can tilt forward and backward. The tilting angle varies when dealing with different forklifts, masts and attachments and is limited at high mast to maintain truck stability. This is useful to know as depending on what materials you are carrying, you may require a higher tilt angle to ensure stable manoeuvrability and avoid any loss of loads.

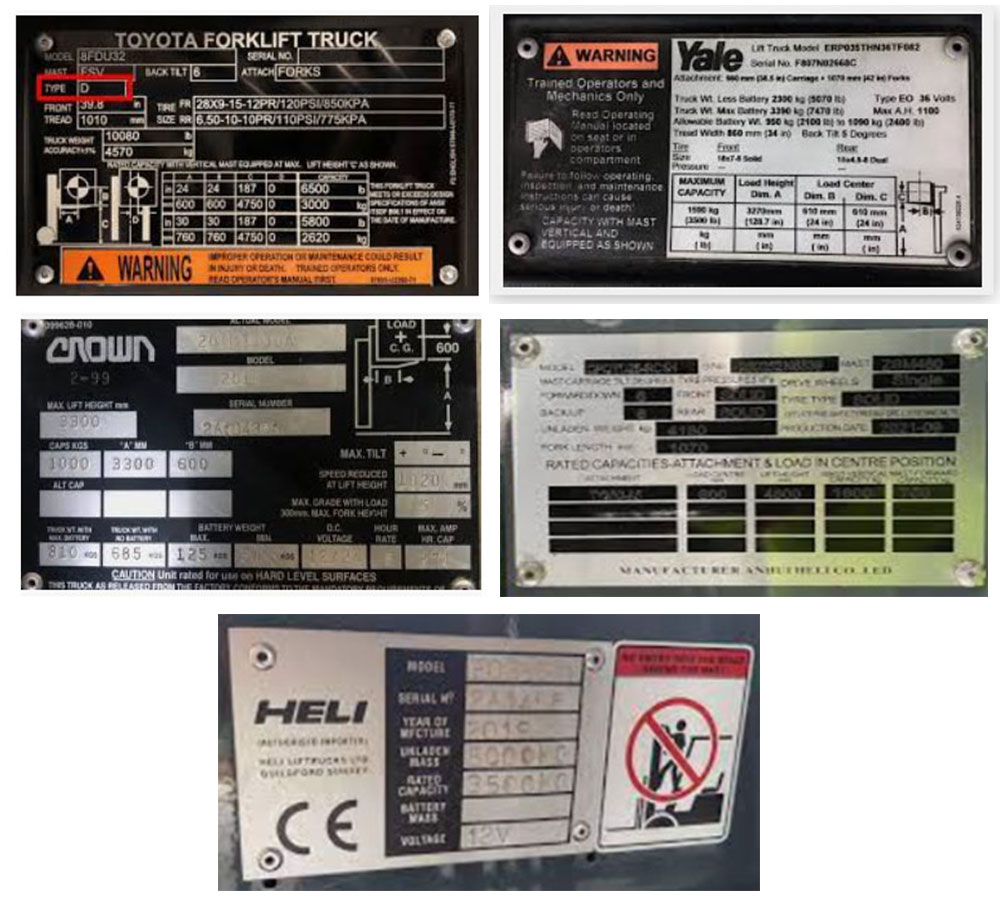

Some examples of forklift load plates are shown below

Understanding The Maximum Capacity

The above information contained in the Forklift Diagram is used to calculate a forklift’s load capacity. This is the maximum safe weight that a forklift is able to carry at a specified load centre.

This stated capacity is listed in the bottom right hand corner of the load plate. It’s important to note that a forklift’s maximum capacity can be reduced by a number of factors including; attachments, longer load centres, and lift height.

If you have any further questions as to how the capacity is specifically derived, you can contact your local expert forklift supplier, and there are also a number of online forklift capacity calculators you can use for further guidance.

Best Safe Practice

Now that you have a better understanding of the data contained in the forklift load plate, it’s important that it forms part of your everyday safety operations.

Training

Adequate training on the understanding and work applicability of the load plate should be undertaken for all relevant forklift operators and maintenance personnel. This should include practical applications such as how different load types and configurations can affect lifting capacities.

Review

The review of the load plate should form part of the safety checks of a forklift at the start of each shift. This enables an operator to check the trucks’ lifting capacity and ensure any new attachments have been factored into capacity limits.

Maintenance

Maintenance personnel should regularly check the readability and accuracy of the load plate. This ensures that any changes to configuration such as attachments are accurately reflected. On occasions based on significant changes and wear and tear, maintenance workers may recalculate load capacities and place an additional updated load plate that complements the original plate from the manufacturer.

Maintaining a safe work environment for everyone is crucial to maintaining productivity.

Since forklifts play such an integral role in operations, it’s important that they operate safely and within their capacity load limits.

A forklift load plate provides essential information about the configuration, design, and limitation of a forklift. It contains important data specific to the particular machine such as the weight, fuel type, and overall load capacity. Achieving a good level of understanding about a forklift’s load capacity will enable an operator to assess a forklift’s limitations and what loads can be safely transported throughout the workplace.

The ongoing training, review, and regular maintenance of a load plate’s workplace applicability needs to form a central part of safety operations to be conducted by all relevant forklift operators and maintenance personnel.

We hope this blog has been informative and helpful. Should you have any further questions on forklift load plates or any other forklift safety issues don’t hesitate to contact the experts here at Forkserve.

We’ve been in business for more than 40 years and stock a large variety of quality forklifts that suit a range of operational environments. We’re renowned for our team of in-house specialist mechanics that can handle all your forklift repair and maintenance needs.

For any of your Forklift needs, why not contact us today.